Secure Dosage and Filling of Formalin for Operating Theaters and Pathological Anatomy Laboratories!

SOLUTION FOR SECURE MANAGEMENT OF HISTOLOGICAL SAMPLES FROM THE OPERATING ROOM TO THE PATHOLOGICAL ANATOMY LABORATORY

THE PROBLEM

Formaldehyde recognized as a category 1B carcinogen based on European regulation N605/2014. Work with formalin concerns operators in the operating room, pathological anatomy laboratories and sample transport.

THE IMPERATIVES

Perfectly preserve biological samples to allow correct diagnosis and all subsequent biomolecular investigations.

Protect operators from exposure to formalin vapors

THE SOLUTION

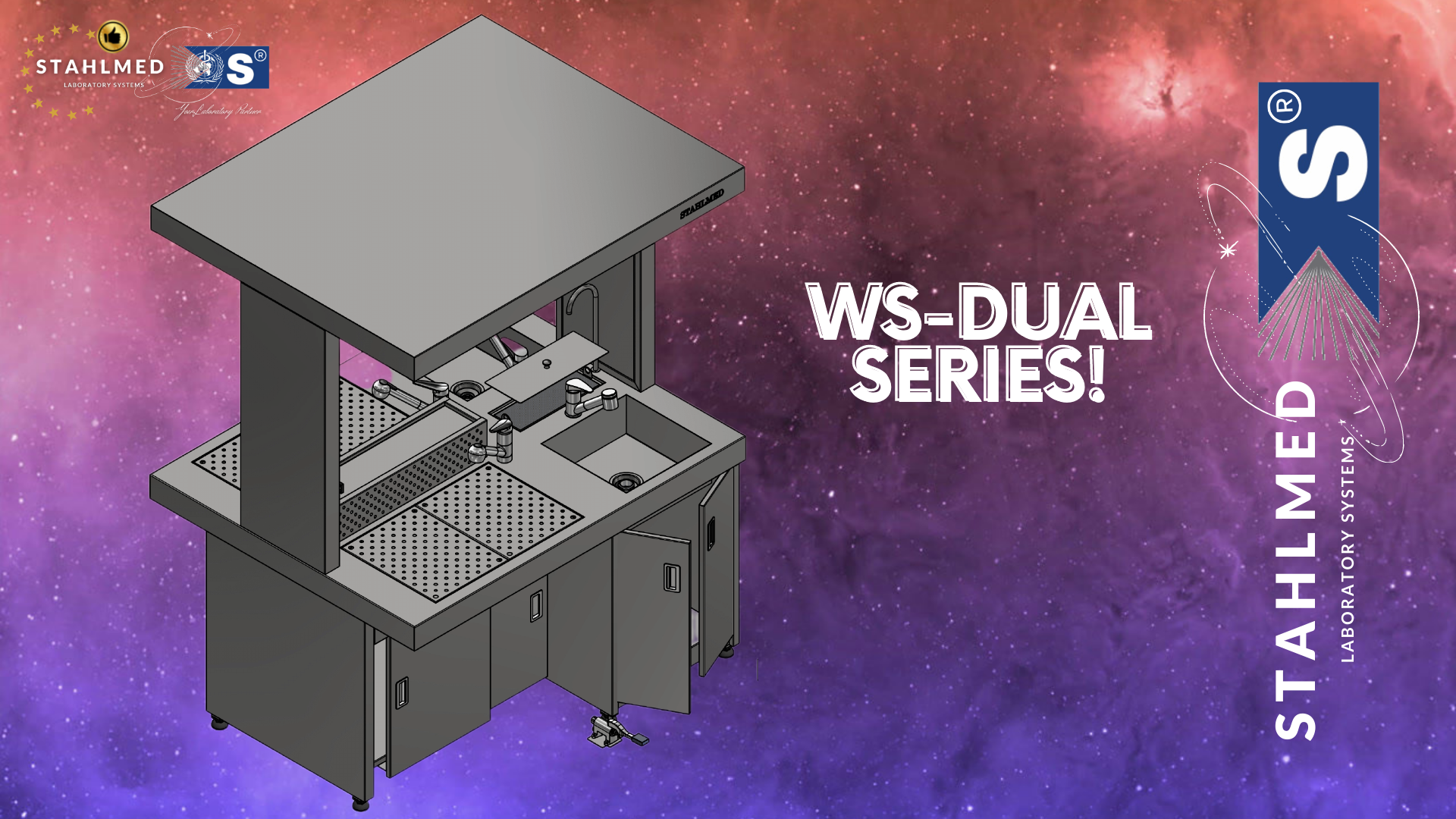

STAHLMED LABORATORY SYSTEMS has acquired know-how and considerable experience over the years in the field of formalin security, to provide a complete solution guaranteeing precise diagnosis, quality and optimal safety for operators, from the pre-analytical phase in the post-analytical phase

YOUR SAFETY FIRST!

§ Safe filling of buckets with 4% buffered formalin, inside a completely closed and ventilated enclosure, guaranteeing the containment of vapors for the safety of users

§ Dispensing of formaldehyde disabled if the motorized front window of the work chamber is not closed

§ Lighting of the working area for the visual control of the filling level of the buckets

§ Filling canister located in the low ventilated cupboard with quick connector to avoid contact with formalin for the safety of users

§ Large touch screen displaying all Formolsafe parameters (ventilation, filtration, pump activation, alarms, etc.)

§ No specific consumables required

§ Filtration of formalin vapors before discharge to the outside (ED6185 INRS)

§ The FORMOLSAFE meets the needs of operating theaters that want a secure system for filling buckets containing samples with 4% buffered formalin, guaranteeing user safety.

§ The FORMOLSAFE makes it possible to fill rigid, standard buckets of all sizes, without the operator being subjected to fumes or contact with the fixer. The volume of formalin dispensed is controlled by the user.

§ To launch a filling program, simply place the container containing the sample inside the FORMOLSAFE enclosure. Once the motorized sliding window is in the closed position, the formalin dispensing pump activates and the dosing of the fixative can begin in complete safety.

§ The FORMOLSAFE uses standard containers available on the market or closed circuit cubitainers with a capacity of 10 or 20 liters.

FIXATION IN THE OPERATING ROOM WITH FORMOLSAFE

– Put the biological sample in the bucket adapted to its size

– Place the buckets in the work enclosure under the tap

– Closing of the motorized sliding window and activation of the formalin pump

– Press the pedal to start the formalin dosage inside the completely closed and ventilated enclosure

– Volume control thanks to the lighting of the work area

– Opening of the motorized sliding window with increased ventilation in order to maintain a minimum flow of 0.5 m/s at the level of the opening.

– Close the bucket with its lid

– Stick the tracking label on the bucket

– Place the bucket in a ventilated cabinet awaiting collection by the pathological anatomy laboratory

TECHNICAL FEATURES

- Safe filling of sample buckets with formalin

- Deactivation of the pump if the front motorized sliding window is not closed

- Activation of distribution by pedal

- Ventilated, closed and illuminated distribution enclosure

- Variation of the ventilation according to the opening of the front window to guarantee a flow of 0.5 m/s minimum at the level of the opening in the front

- Ventilated storage cupboard for formaldehyde canisters or cubitainers with sliding shelves such as retention bins

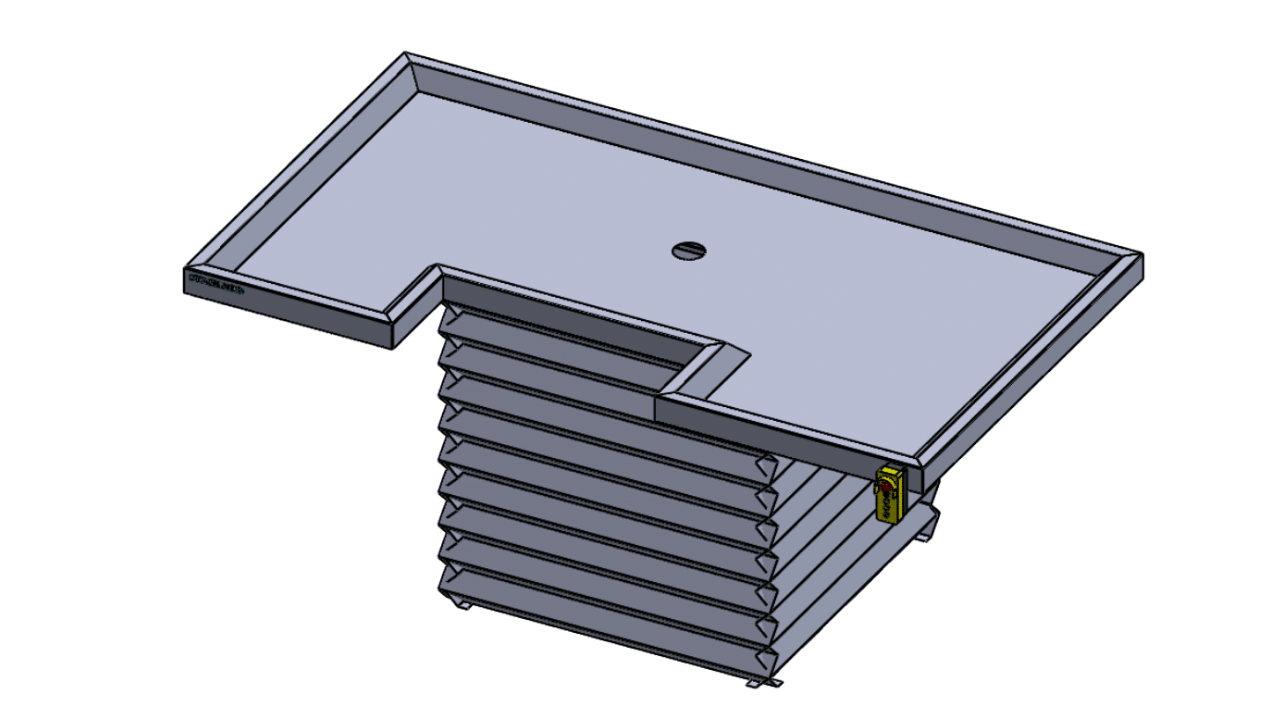

- Recovery tank under the perforated tray in case of accidental spillage, connected to a recovery canister with full canister level alarm located in the low ventilated cupboard

- Built-in carbon filter for aldehydes, optional HEPA filter

- Active suction during all phases of use of the instrument

- Large color touch screen to view all working parameters

- Connection tapping for discharge to the outside above the device D 200 mm

- In France, FORMOLSAFE requires connection to an external drain (ED6185 INRS).

- Equipped with a filter for formaldehyde and an extractor in the upper part

- No specific consumables required

- Ease of use

- Ease of installation and maintenance

- Small footprint W 750 x D 782 x H 2200 mm

| Material |

AISI 304 stainless steel for body,AISI 316 Quality 1.5mm for Worktop and safety glass |

| Worktop Height |

900 mm |

| Lenght |

750mm |

| Depth |

782 mm |

| Height |

2200 mm |

| Duct Connector |

Ø 200 mm |

| Weight |

160 kg |

| Installed Electrical Power (Nominal) |

|

| Maximum Absorption |

|

| Power Supply |

220 Vac – 50 Hz ±10% |

| Auxiliary Circuit Voltage |

|

| Protection Class |

I |

| IP |

IPX0 |

| Ventilation |

750 m3/h (only during one work cycle (about 3 minutes) |

| Noise Level |

79 dB (A) (only during a work cycle (about 3 minutes) |

| Filters |

1 Formaldehyde filter, 1 HEPA filter (optional) |

| Working Temperature |

+15°C < T < +35°C |

| Relative Humidity |

5% < UR% < 90% |

| Formalin Container |

Max 20 liters |

Last Comments