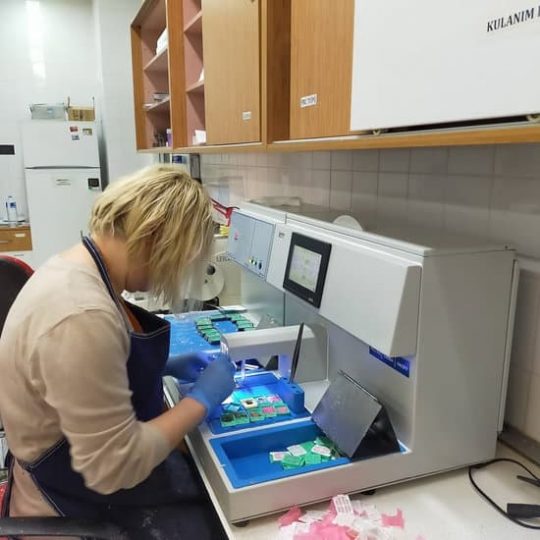

Tissue Embedding System

Custom buıld ıs avaılable

Stahlmed MXSTH 571 – MXSTH 632 isa modern paraffin embedding station with microprocessor control system. It is designed for use in pathology laboratories and for embedding histological tissue samples only in molten paraffin for the following tasks:

• To embed the sample, melt the solid paraffin and keep the melted paraffin at the required temperature.

• Pour paraffin into embedded molds where the samples are placed.

- The device ensures that all existing applications are combined in paraffin embedding.

- The device can be controlled under the microprocessor control.

- The device can be one-piece or two-piece modular.

- The start time of the device can be programmed differently for each day of the week, thus saving energy.

- It has a large touch LCD screen that shows all data about the device and shows all data.

- The information in the menus opened on the screen can guide the user.

- The device is insulated against paraffin leaks.

- The device has a non-disposable mesh porous filter system to ensure that the wax used remains clean.

- The device has a large storage tank with a heater that can take at least 150 block molds.

- The device has a wide stainless steel tank with a capacity of at least 150 cassettes, which allows the storage of baskets from tissue tracking devices.

- The temperature of this section can be adjusted between 0 – 70 ºC (+/- 1ºC).The device has a paraffin tank with a capacity of at least 4 liters, which allows long working periods.

- The cold plate should be capable of holding at least 60 blocks, and this part can be cooled to 0 to -20 ° C.

- Hot plate can be adjusted between 0 – 70 ºC (+/- 1ºC).The temperature of the tissue burial molding chamber can be adjusted between 50-70ºC (+/- 1ºC).

- The temperature of the paraffin tank can be adjusted between 0 – 70 ºC (+/- 1ºC).The working table, cassette opening section and collet heater sections are designed to transfer extra paraffin to a single heated chamber through the channels.

- Waste paraffin can be discharged from this compartment.

- There are at least 4 heated collet places on the device and these places are made of stainless material.

- The device operates at 220 V, 50 Hz.Made in Turkey and one-to-one product exchange guaranteed