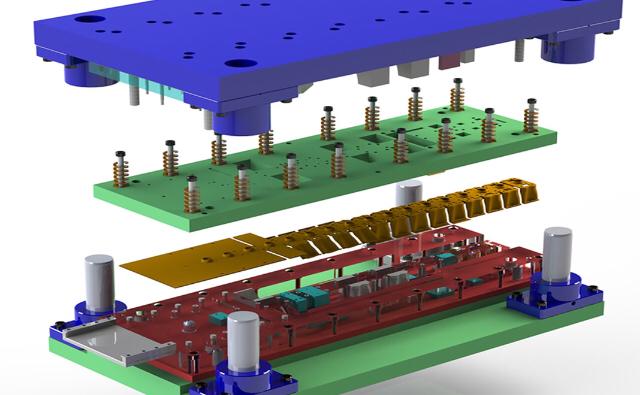

Thanks to the progressive molds, mass production can be made with minimal need for manpower. In order to benefit from the progressive sheet metal molds during the forming stages of the metal sheet strips, it is of great importance to make the correct placement of the sheet metal during the design and to determine the processes correctly.

In determining the operations with progressive molds, software that simulates metal sheet forming should be used, and in design, software with modules customized for mold design should be used.

Plastering Molds

The form of forming, which is generally used in the process of obtaining hollow, seamless containers or different parts from flat sheet metals, is also called spinning, also known as drawing. As can be seen from the description of drawing, the number of parts that can be obtained from this type of forming process is infinite.

Sheet metal cutting molds are metal molds that are used to separate parts of desired profile or dimensions from flat sheet or strip sheets within specified tolerances and turn them into final products. The male punch and female punch, which are suitable for the shape of the part to be cut, are the main parts. As the male punch passes through the fixed female punch, the material in between is cut with wedge-shaped blades. A high degree of accuracy and superior quality are the main features of sheet metal molding processes.

As Stahlmed Laboratory Systems, we provide you the mold by designing and manufacturing! For more information and the quote request, contact with the Stahlmed’s Technical Experts.

Last Comments